Our laboratory

DIAMONDS GROWN IN THE LABORATORY

In our laboratory, we reproduce the natural process of terrestrial crystallization of carbon into diamonds, which are chemically, optically and physically identical to the diamonds mined, while they are priced up to 40% lower and free from impurities. Are laboratory diamonds real diamonds? (Also called artificial diamonds or lab-grown diamonds) The answer is very simple – yes. The only thing that distinguishes a diamond created in a laboratory from a natural diamond is its origin. The laboratory-created diamond is “grown” inside the laboratory using advanced HPHT technologies (high temperature and high pressure), which reproduce the natural process of growing diamonds. The result is such a diamond, like a natural diamond, differing only in its origin.

Each diamond created in the laboratory is grown by using advanced HPHT technology.

and involves obtaining diamonds at temperatures above 1400 degrees and pressures of about 5 GPa using the temperature gradient method. The installation, which is a multi-punch hydraulic press, compresses a special container – a growth cell, inside which is a catalyst and graphite.

HIGH-PRESSURE HIGH-TEMPERATURE, or HPHT, recreates a natural diamond growth environment identical to the conditions of growth deep inside the Earth’s interior.

The growth cell contains all the elements necessary for growing a diamond, including seed, highly purified graphite and a catalytic mixture consisting of metals and powders. The cell is located in the center of the HPHT camera. Apply constant temperatures reaching 1300 degrees Celsius and more than 50,000 atmospheres. The catalysts inside the cell are the first to respond to the added heat and pressure, and the growth cell goes from solid to molten form.

The molten catalyst solution causes the graphite to dissolve inside the cell. Once all the necessary conditions are met, the cooling process begins.

This process takes place over several days and allows carbon atoms to build up onto the seed cell. Subsequently, the cell is removed from the HPHT press after the growth cycle is completed. A new rough diamond is removed and cleaned to prepare for final cutting and polishing.

The entire process of growing HPHT requires a constant controlled environment for producing gem-quality diamond.

This allows you to control the synthesis and make a change in the structure of the diamond, allowing you to get rough diamonds with desired characteristics. Each diamond at the end of the entire growth cycle has predictable and consistent characteristics, including color, purity and size.

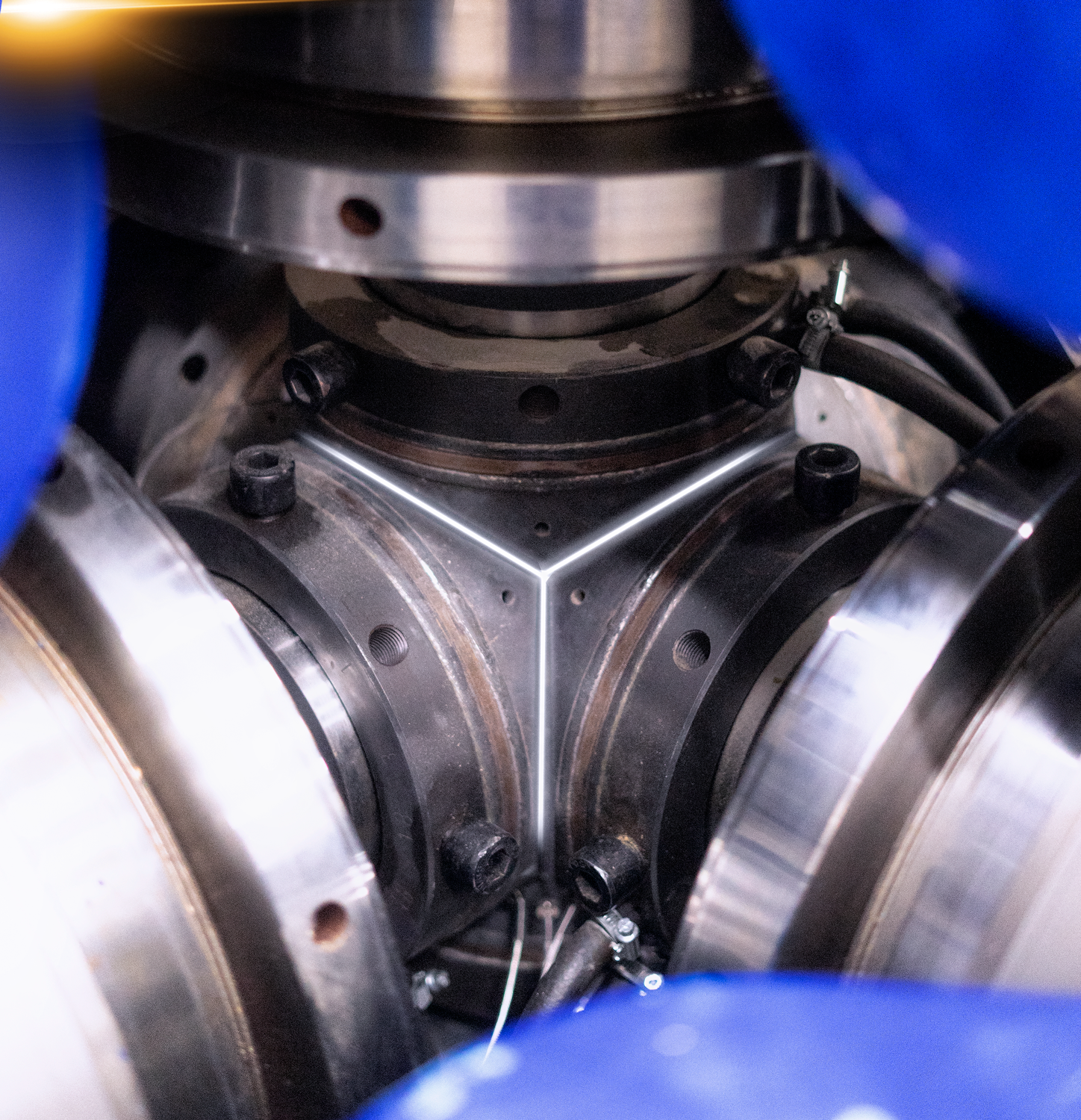

As part of the HPHT process, there are three main tools that are used to change the synthesis parameters.

Bars Press – is the most effective tool for synthesis. It uses a combination of internal and external anvils to apply hydraulic pressure in the growth chamber.

Belt Press is a fundamental technology for growing diamonds. It can produce several diamonds in one cycle, using two large anvils, which are compressed to create the necessary pressure.

Cubic Press – The Cubic Press can use six separate anvils to create the necessary pressure for the growth of diamond crystals.

Belt Press is a fundamental technology for growing diamonds. It can produce several diamonds in one cycle, using two large anvils, which are compressed to create the necessary pressure.

Cubic Press – The Cubic Press can use six separate anvils to create the necessary pressure for the growth of diamond crystals.

Partnership

We are always interested in expanding our partner network, and if you are interested in individual projects based on our advanced technologies for growing nitrogen-free diamond single crystals according to the highest quality standards, surpassing natural diamonds in size and characteristics, you can always contact us about the possibility of partnership and collaboration.

SCIENCE

how we create our diamonds?

The process of creating a natural and synthetic diamond is extremely similar – only one occurs naturally, and the other occurs in the laboratory. We make science simple and want to share with you our innovative and advanced HPHT synthetic diamond technology.